A super solution for heavy pollution

Dry ice cleaning is suitable as a compact and practical solution for many surfaces. It makes cleaning a lot easier. This allows components and plastics to be optimally cleaned with dry ice. Cleaning is also done without chemicals and quickly. The handling is very simple.

Low operating costs

Dry ice cleaning produces low operating costs. The solution is environmentally friendly and, above all, sustainable. Hygienic cleanliness is achieved. The cleaning machines are easy to use and compact and the „Dry Ice“ brings many advantages. All kinds of dirt and deposits are removed. These include oils and fats. But other organic adhesions and deposits can also be removed. Germs and bacteria also disappear permanently from the surface. Mold and viruses are also eliminated. Cleaning is possible thoroughly and without water. Aggressive chemical cleaning agents are not required. In addition, dry ice cleaning is suitable for almost all surfaces.

Perfect cleanliness

This method ensures perfect cleanliness even for machines that are often not easy to clean. In sand blasting, for example, sand or the glass granules are left as waste and must be disposed of. There is no residue or waste in the dry ice version. The cleaning afterwards falls away. With the dry ice pellets, all dirt particles dissolve without any problems and everything is completely converted into CO2. What remains is perfect cleanliness and no rubbish, no polluted sewage or the like. Other advantages in dry ice jet cleaning are that you have no pre- and no rework. The pellets come into all cracks, joints, nooks and crannies. There is hardly any machine downtime and the cleaning is effective, fast and cost-effective. In addition, the method is environmentally friendly cleaning.

Cold times acceleration

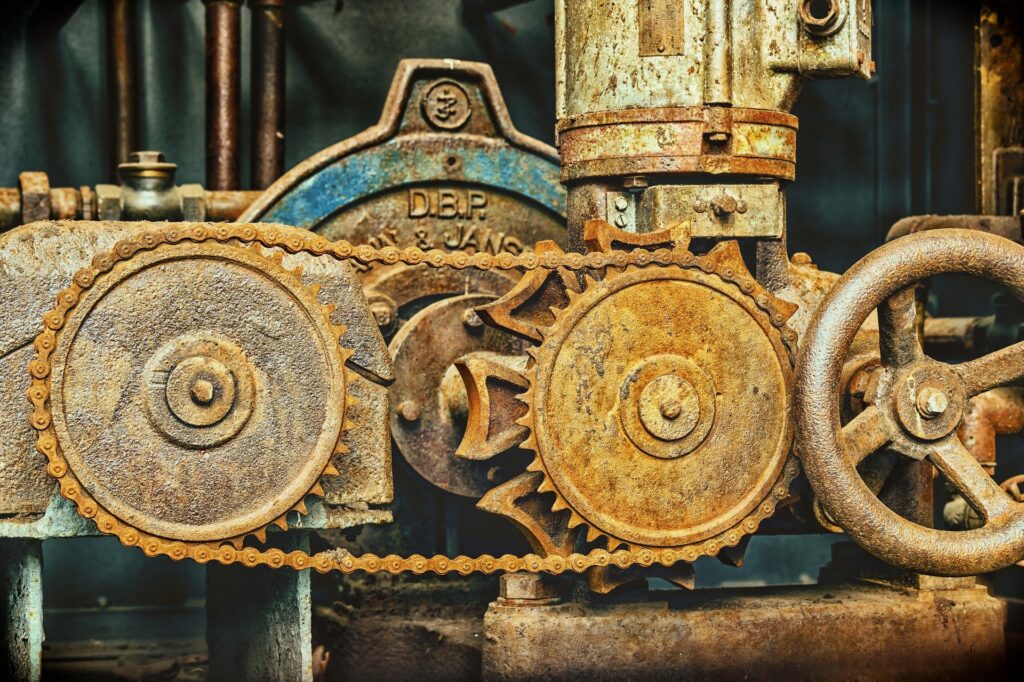

The effective cleaning method works with the formula cold times acceleration. This is where compressed air, together with the dry ice pellets, will lead to an effective result. The pellets clean at high speed and simply remove the dirt. This is an effective and material-friendly method that is becoming more and more trendy. It can also be used to clean many areas. No chemical additive is required. The pellets dissolve without residue and sewage is also not produced. Dry ice cleaning is used, for example, in the basic and maintenance cleaning of production machines or in welding robots. It can also be cleaned for conveyor belts and painting systems.

The work is easy to do. Dry ice blasting is also used by printing presses. The press cylinders and the tools are also cleaned. Everything looks like new again. This method can also be of great benefit to the wood and electrical industry. Woodworking machines, generators, control cabinets and turbines are quickly cleaned. In the plastics and packaging industry, the injection moulds of the respective production lines are thus freed from deposits. Rubber and silicones can also be cleaned of paints, paints and other dirt. The dry ice method is also used in the automotive industry.

Look at white-lion.eu!